In numerous constructions for different cylinder head and manifold gaskets are in vogue. Below mentioned are some of the most populartypes manufactured by King Seal, other special forms can be tailor made to customer's drawings. Cylinder head and Manifold Gaskets Cylinder head gaskets have several construction. No single construction is ideal for all applications. The gasket design and construction is worked out for each type of engine and exhaustive testing is carried out to determine the correct version. No Retorque Cylinder Head Gaskets are nowadays very common and desirable. Some engines. require the cylinder head to be retorqued. Retorque-type gaskets take a set after initial engine operation and relax to the point where retorquing is needed to restore proper clamping force. In the long run, the extra labour and expense of using a retorque cylinder head gasket makes the repair more expensive than using a no-retorque design.

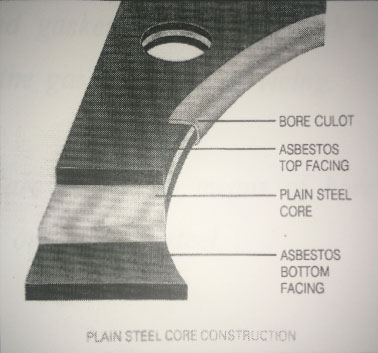

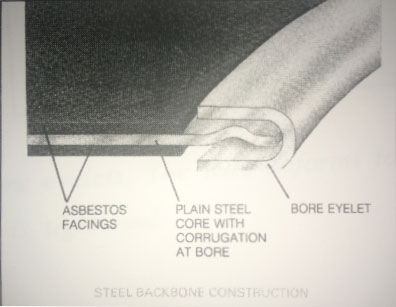

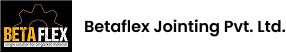

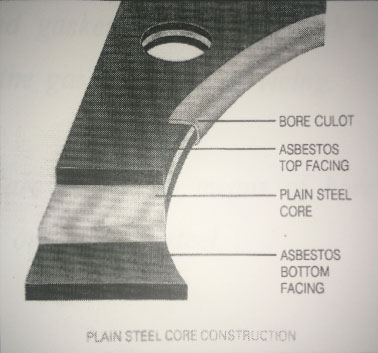

Plain steel Core/ Steel Back Bone Construction :- Plain steel Core/ Steel Back Bone Construction :-

This type of construction is applicable to both cylinder head and manifolds, it consist of asbestos/ aramid fibre facings bonded to a tinplated or zinc coated steel core. The adhesive used is resistant to oils, fuels & coolants, the strength of the material makes an ideal medium for sealing engines with narrow bore bridges.

In case of steel backbone the facing material which is cut back from the cylinder bore area. An eyelet is then closed over the protruding core which itself can be embossed to improve sealing performance, t his type of head gasket is used on diesel and racing engines In case of steel backbone the facing material which is cut back from the cylinder bore area. An eyelet is then closed over the protruding core which itself can be embossed to improve sealing performance, t his type of head gasket is used on diesel and racing engines

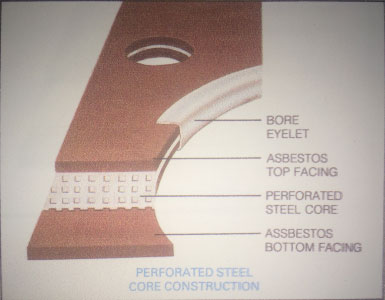

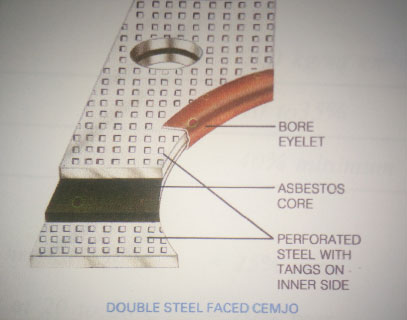

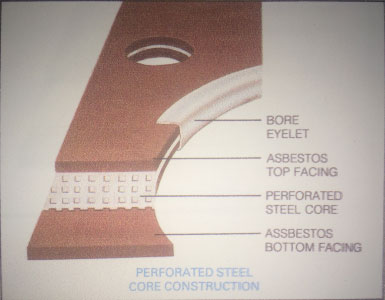

Perforated Steel Core Construction:- Perforated Steel Core Construction:-

These are composites with a perforated and tanged steel core with asbestos/ Non-asbestos beater jointing and provide a mechanical bond between the facings and core for improved durability. An adhesive can also be used to bond the facings and prevent coolant leakage along the core line. This construction is used for medium to heavy duty cylinder gaskets as well as for smaller engines. The cylinder bores of the above gasket are sealed by the means of bore eyelets made of steel copper or stainless steel.

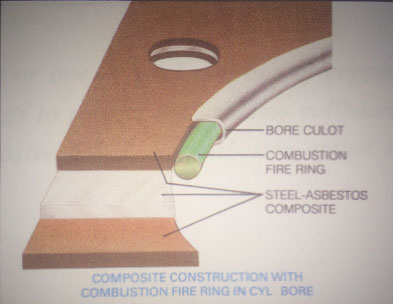

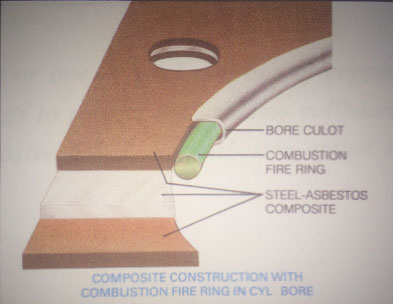

Composites with combustion fire rings in cylinder bores :- Composites with combustion fire rings in cylinder bores :-

Cylinder head gaskets of high performance engines incorporate a cylinder bore construction wherein a soft metallic wire (ferrous or non-ferrous depending on suitability of application) is fitted within the bore eyelets. The wire deforms to form a good seal when the cylinder head is tightened

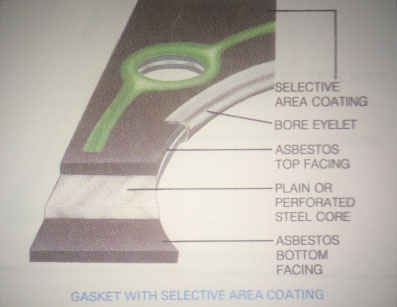

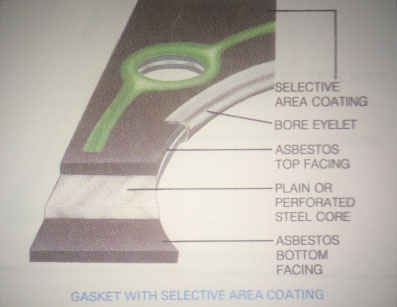

Gasket with Selective area coating :- Gasket with Selective area coating :-

King Seal has also introduced another construction feature namely Selective are coating on gaskets. In some cylinder head gaskets it is necessary to reinforce local areas of the gasket body to equalise the load and to improve the sealing characteristics. Coating may be done either on one or both sides of gaskets This process of selective coating is achieved by applying a silicone compund through a silk screen on to the surface.

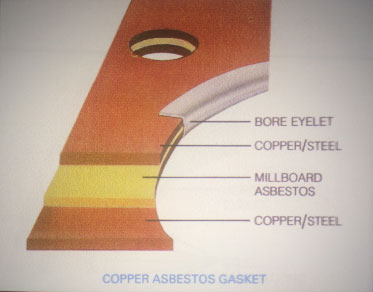

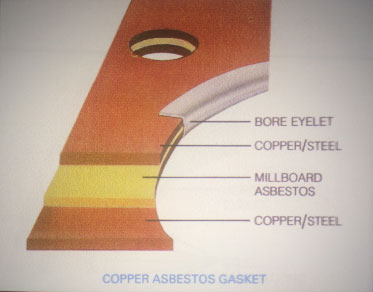

Copper and Metal clad gaskets :- Copper and Metal clad gaskets :-

Although copper asbestos/ non-asbestos and metal clad design has been superseded by various new constructions, it is still popular in light and medium duty engines because of its high compressibility characteristics. In this construction, a layer of millboard is sandwiched between two sheets of copper or one steel and one copper. All ports are provided with metallic rings to protect the millboard from all heat and pressure.

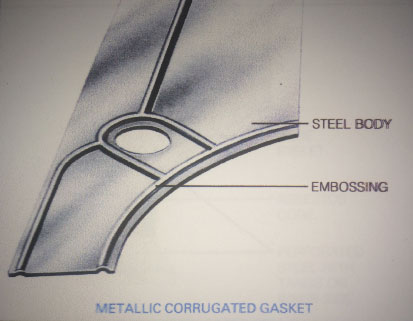

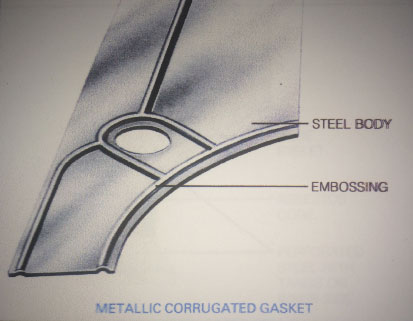

Metallic Corrugated gaskets :- Metallic Corrugated gaskets :-

This construction is found in some designs of both, cylinder head and manifold gaskets. It comprises of a plain metallic sheet with suitable corrugations. It has high torque retention properties but needs adequate clamping load to provide perfect sealabilty. Embossed exhaust manifold gaskets are used in heavy duty diesel engines for better accommodation of the large thermal movements.

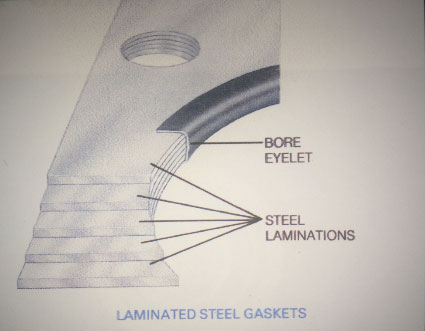

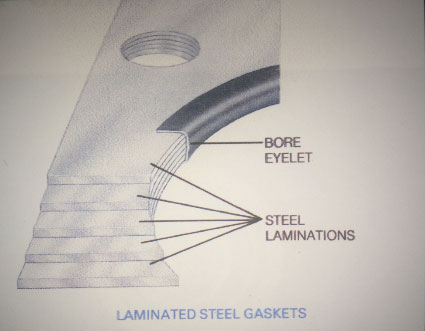

Metal laminated steel gaskets :- Metal laminated steel gaskets :-

These cylinder head gaskets are also used in heavy duty diesel engines. Its construction comprises of a number steel laminations with different thicknesses to meet its compressibility characteristics. These type of gaskets apart from giving more strength are also adequately compressible to form a good seal. Metal laminated steel cylinder head gaskets come with a wide range of features including silicon rubber reinforcements, corrugations and special surface coatings.

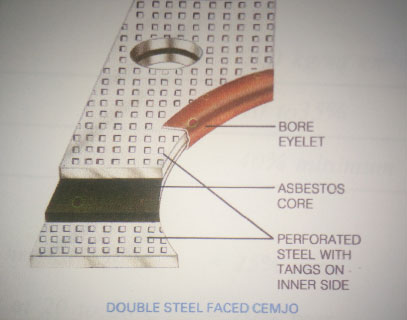

Double Steel faced Cemjo :- Double Steel faced Cemjo :-

This gasket is made up of perforated steel faces to a soft core, this soft core is either asbestos or non-asbestos beater jointing. It is frequently fitted to diesel engines with turbo chargers where high temperatures and exhaust flange movement is likely. The sealing properties of the above can be enhanced by the addition of steel eyelets to the gasket exhaust ports.

Spiral Wound and Exhaust gaskets :-

Spiral wound gaskets are special semi-metallic gaskets of great resilience, hence they are highly recommended in heavy duty operating conditions, these gaskets are manufactured by spirally winding a V-shaped metal strip along with asbestos/ non-asbestos Millboard/ Beater Jointing used as filler material. The metal strips hold the filler, which helps the gasket and gives it high resistance and resilience.

|

Plain steel Core/ Steel Back Bone Construction :-

Plain steel Core/ Steel Back Bone Construction :-  In case of steel backbone the facing material which is cut back from the cylinder bore area. An eyelet is then closed over the protruding core which itself can be embossed to improve sealing performance, t his type of head gasket is used on diesel and racing engines

In case of steel backbone the facing material which is cut back from the cylinder bore area. An eyelet is then closed over the protruding core which itself can be embossed to improve sealing performance, t his type of head gasket is used on diesel and racing engines Perforated Steel Core Construction:-

Perforated Steel Core Construction:-  Composites with combustion fire rings in cylinder bores :-

Composites with combustion fire rings in cylinder bores :- Gasket with Selective area coating :-

Gasket with Selective area coating :- Copper and Metal clad gaskets :-

Copper and Metal clad gaskets :- Metallic Corrugated gaskets :-

Metallic Corrugated gaskets :- Metal laminated steel gaskets :-

Metal laminated steel gaskets :- Double Steel faced Cemjo :-

Double Steel faced Cemjo :-

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese